This manual provides essential information for identifying and ordering replacement parts for the Skyjack SJIII 3219 scissor lift, ensuring proper maintenance and safety standards.

1.1 Purpose of the Parts Manual

The purpose of the Skyjack SJIII 3219 Parts Manual is to provide users with a comprehensive guide for identifying, locating, and ordering genuine replacement parts. It ensures proper maintenance, repairs, and safety by detailing component assemblies, exploded diagrams, and part lists. This manual helps users maintain equipment performance, prevent damage, and comply with manufacturer standards. By using authorized parts, users can ensure reliability, safety, and adherence to warranty conditions, avoiding potential risks associated with non-genuine components.

1.2 Scope of the Manual

The Skyjack SJIII 3219 Parts Manual covers essential components for the SJIII 3215 and SJIII 3219 scissor lifts, providing detailed exploded diagrams and part lists. It includes platform, scissor, and base assemblies, along with hydraulic and electrical components. The manual also outlines tools required for maintenance, safety precautions, and environmental compliance. Designed for technicians and operators, it ensures accurate identification and ordering of genuine Skyjack parts, supporting efficient repairs and maintaining equipment performance. The scope is limited to replacement parts, excluding operational procedures covered in separate manuals.

1.3 Importance of Using Authorized Replacement Parts

Using Skyjack-authorized parts ensures compliance with safety standards, maintains warranty validity, and guarantees optimal performance. Unauthorized parts may void warranties and compromise safety. They are engineered to meet exact specifications, ensuring reliability and durability. Always verify part compatibility through Skyjack’s support resources to avoid malfunctions. This adherence ensures your equipment operates safely and efficiently, protecting both the machine and its operators. Refer to the manual for correct part identification and ordering procedures to maintain your Skyjack SJIII 3219’s integrity and performance over time.

General Information About the Skyjack SJIII 3219

The Skyjack SJIII 3219 is a reliable electric scissor lift designed for indoor and outdoor applications, offering a maximum platform height and robust performance for various tasks.

2.1 Overview of the SJIII 3219 Scissor Lift

The SJIII 3219 is a high-performance electric scissor lift designed for versatility in indoor and outdoor applications. With a robust design and reliable operation, it offers a maximum platform height and a strong load capacity, making it ideal for construction, maintenance, and industrial tasks. Its compact footprint allows for easy maneuverability in tight spaces, while its durable construction ensures long-term performance and reliability in demanding environments.

2.2 Key Features and Specifications

The SJIII 3219 features a maximum lift height of 19 feet, a 500-pound load capacity, and a compact 32-inch wide chassis, making it suitable for confined workspaces. Equipped with electric motors, it provides quiet, emission-free operation ideal for indoor environments. The scissor lift includes a sturdy platform with extension capabilities, enhancing workspace flexibility. Its robust steel construction ensures durability, while proportional controls offer precise movement and operator ease. These specifications ensure reliable performance for various industrial and construction applications, meeting the demands of challenging work environments effectively.

2.3 Target Audience for the Manual

This manual is designed for service technicians, maintenance personnel, and parts managers responsible for the Skyjack SJIII 3219 scissor lift. It also serves operators, rental companies, and dealerships needing detailed parts information. The manual provides essential data for identifying and procuring replacement parts, ensuring adherence to safety and performance standards. By using authorized parts, users maintain equipment reliability and compliance with manufacturer guidelines, which is critical for optimal functionality and workplace safety. This resource is indispensable for anyone involved in the maintenance or operation of the Skyjack SJIII 3219.

Structure of the Parts Manual

This manual is structured with a detailed table of contents, organized parts information, and exploded diagrams for easy navigation. It covers platform, scissor, and base assemblies.

3.1 Table of Contents

The table of contents provides a clear overview of the manual’s structure, listing sections such as general information, exploded diagrams, maintenance best practices, and troubleshooting guides. It serves as a quick reference for users to locate specific topics efficiently. Each section is further divided into subsections, ensuring easy access to detailed information. The table of contents is designed to help users navigate the manual seamlessly, making it an essential starting point for anyone using the Skyjack SJIII 3219 parts manual.

3.2 Organization of Parts Information

The parts information is organized by component and assembly, with detailed exploded diagrams and part lists for easy identification. Each section corresponds to specific parts of the Skyjack SJIII 3219, such as the platform, scissor, and base assemblies. The manual uses clear part numbers and descriptions, cross-referenced with diagrams to simplify the identification process. This structure ensures users can quickly locate the information they need for maintenance, repairs, or replacements, making the manual a user-friendly resource for technicians and operators alike.

3.3 How to Locate Specific Parts

To locate specific parts, refer to the detailed index or table of contents, which direct users to relevant sections. Use part numbers and descriptions to identify components quickly. Exploded diagrams provide visual guidance, while part lists offer numerical references. Cross-referencing between diagrams and descriptions ensures accuracy. If a part is not found, contact Skyjack’s Parts Department for assistance. This systematic approach streamlines the process, making it efficient for technicians and operators to find and order the correct replacement parts for the Skyjack SJIII 3219 scissor lift.

Types of Documentation Available

The Skyjack SJIII 3219 documentation includes operating manuals, parts manuals, service manuals, technical animations, and environmental data sheets to support equipment operation, maintenance, and repair.

4.1 Operating Manual

The Skyjack SJIII 3219 Operating Manual provides detailed instructions for the safe and efficient operation of the scissor lift. It includes pre-operational checks, controls overview, and emergency procedures. The manual is designed for operators and technicians, offering clear guidelines for routine inspections, safety protocols, and troubleshooting common issues. It also outlines proper loading and unloading procedures to ensure operator and equipment safety. By following the manual, users can maximize productivity while minimizing risks associated with equipment operation. This document is essential for anyone involved in the daily use or maintenance of the SJIII 3219 scissor lift.

4.2 Parts Manual

The Skyjack SJIII 3219 Parts Manual is a comprehensive guide for identifying and ordering replacement parts. It features exploded diagrams and detailed part lists for the scissor lift’s components, including the platform, scissor, and base assemblies. This manual helps users locate specific parts quickly and ensures compatibility with the equipment. It also emphasizes the importance of using authorized Skyjack parts to maintain safety and performance. The manual is an indispensable resource for technicians and service personnel responsible for maintaining or repairing the SJIII 3219 scissor lift.

4.3 Service Manual

The Skyjack SJIII 3219 Service Manual provides detailed procedures for maintaining, troubleshooting, and repairing the scissor lift. It includes step-by-step instructions for servicing hydraulic and electrical systems, as well as routine maintenance tasks. The manual covers diagnostic techniques and repair guidelines for various components, ensuring technicians can address issues effectively. It also emphasizes safety protocols and best practices for performing repairs. This resource is essential for technicians and service personnel to ensure the equipment operates safely and efficiently. Regular use of the Service Manual helps extend the lifespan of the Skyjack SJIII 3219.

4.4 Technical Animations and Support Resources

Technical animations and support resources provide visual guides for understanding complex procedures on the Skyjack SJIII 3219. These animations detail component interactions, diagnostic processes, and repair steps, making troubleshooting easier. Support resources include instructional videos, interactive diagrams, and downloadable guides. They are accessible via the Skyjack Parts and Service Support Portal, offering comprehensive assistance for maintenance and repairs. These tools enhance technician efficiency and ensure accurate execution of tasks. Additionally, Skyjack’s customer support team is available for further assistance, guaranteeing optimal equipment performance and safety. These resources are continually updated to reflect the latest technical advancements.

Exploded Diagrams and Part Lists

This section provides detailed exploded diagrams and comprehensive part lists for the Skyjack SJIII 3219, covering platform, scissor, base, hydraulic, and electrical components for accurate identification and ordering.

5.1 Platform Assembly

The platform assembly section of the Skyjack SJIII 3219 parts manual details the components of the lift’s work platform, including floor pans, guardrails, and control systems. Exploded diagrams provide a visual breakdown of each part, aiding in identification and ordering. This section is essential for maintenance and repair, ensuring users can locate and replace components efficiently. The manual emphasizes the importance of using authorized parts to maintain safety and performance standards. Detailed part lists correspond to the diagrams, making it easier to identify and source necessary replacement items for the platform assembly.

5.2 Scissor Assembly

The scissor assembly section outlines the structural components of the SJIII 3219, including the scissor arms, pins, and linkages. Exploded diagrams and part lists provide detailed visuals and descriptions, enabling users to identify and order replacement parts accurately. This section is crucial for diagnosing and addressing wear or damage to the scissor mechanism, ensuring proper lift functionality and safety. The manual highlights the importance of using genuine Skyjack parts to maintain optimal performance and compliance with safety standards. Cross-referencing with the parts manual ensures correct part selection for repairs.

5.3 Base Assembly

The base assembly section details the components of the SJIII 3219’s foundation, including the chassis, wheels, and control modules. Exploded diagrams and part lists provide a clear view of the base structure, aiding in the identification of replacement parts. This section is vital for addressing issues related to mobility and stability, ensuring the lift operates safely and efficiently. The manual emphasizes the importance of using genuine Skyjack parts for maintaining performance and safety compliance. Detailed cross-referencing helps users locate and order the correct components efficiently.

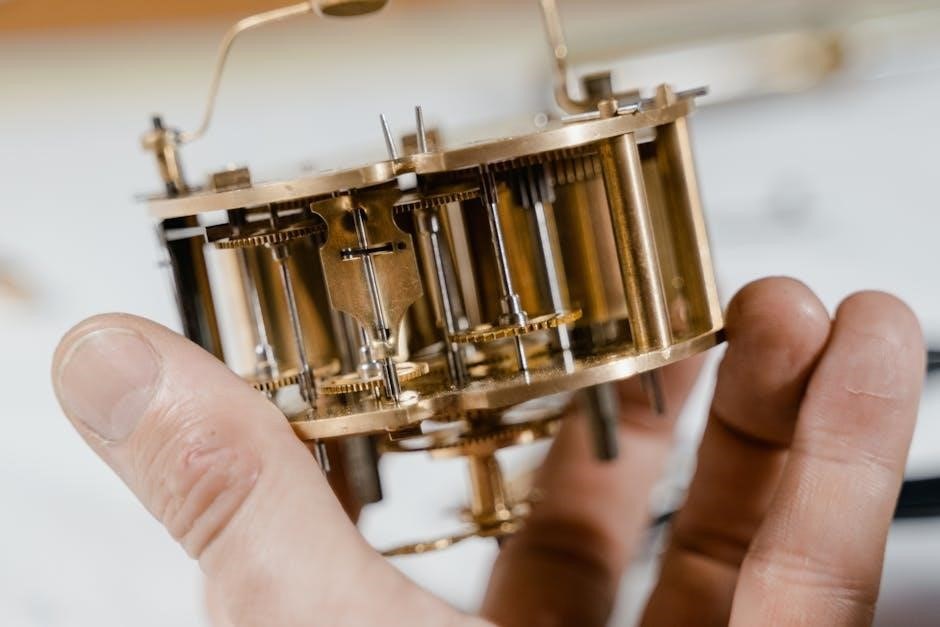

5.4 Hydraulic and Electrical Components

This section provides detailed diagrams and part lists for the hydraulic and electrical systems of the SJIII 3219. It covers pumps, motors, valves, and wiring harnesses, ensuring users can identify and replace components efficiently. The manual emphasizes the importance of using authorized parts to maintain system performance and safety. Exploded views and cross-referencing tools help technicians locate specific parts quickly. Proper maintenance of these systems is crucial for the safe operation of the scissor lift, and this section offers clear guidance for troubleshooting and repair.

Navigating the Parts Manual

Mastering navigation of the Skyjack SJIII 3219 Parts Manual ensures quick access to diagrams, part lists, and essential information for maintenance and repair tasks.

6.1 Understanding Part Numbers and Descriptions

Part numbers and descriptions are critical for accurate identification and ordering. Each component in the SJIII 3219 is assigned a unique identifier, cross-referenced with detailed descriptions to ensure clarity. This system helps users quickly locate specific parts within the manual, reducing errors and downtime. Authorized Skyjack parts are guaranteed to meet performance standards, ensuring reliability and safety. Always verify part numbers before ordering to maintain equipment integrity and compliance with manufacturer specifications.

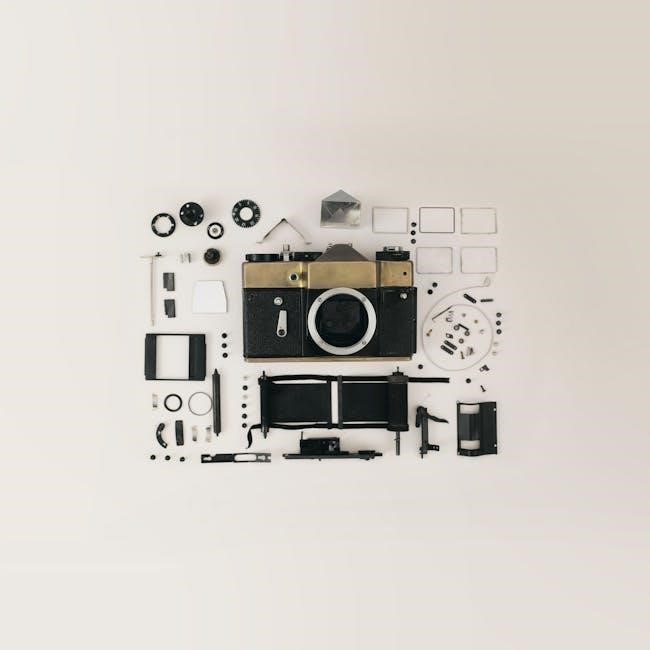

6.2 How to Read Exploded Diagrams

Exploded diagrams visually break down equipment components, showing their relationships and assembly order. Each part is numbered and labeled, with reference numbers linked to descriptions and part numbers in adjacent lists. Use these diagrams to identify specific components, their locations, and how they interact. Cross-reference with the parts list to ensure accurate ordering. This visual guide simplifies identification and ordering, reducing errors. Always verify part compatibility using the manual or by contacting Skyjack support for assistance.

6.3 Cross-Referencing Parts with the Manual

Cross-referencing parts involves matching component numbers from exploded diagrams to descriptions in the parts list. This ensures accurate identification and ordering. Use part numbers and descriptions to locate items in the manual. Verify compatibility by checking specifications and diagrams. If unsure, consult the Skyjack Parts Department or online portal for clarification. This process minimizes errors and ensures correct replacement parts are ordered, maintaining equipment performance and safety. Always double-check references before finalizing orders.

Maintenance and Repair Best Practices

Regular inspections and timely repairs are crucial for optimal performance. Always use authorized Skyjack parts and follow safety guidelines to ensure reliability and operator safety.

7.1 Pre-Maintenance Checks

Before performing any maintenance on the Skyjack SJIII 3219, ensure the machine is on level ground and all systems are powered down. Conduct a visual inspection for wear or damage, checking hydraulic lines, electrical connections, and scissor mechanisms. Ensure all safety locks are engaged and refer to the parts manual for specific guidance. Always wear protective gear and follow established safety protocols to prevent accidents during the inspection process. This step is critical for ensuring a safe and effective maintenance routine. Proper preparation helps identify potential issues early, preventing costly repairs and downtime. By adhering to these checks, operators can maintain the machine’s longevity and reliability. Regular checks also ensure compliance with safety standards, safeguarding both the equipment and the personnel involved in its operation.

7.2 Tools and Equipment Required

Proper tools and equipment are essential for maintaining the Skyjack SJIII 3219. Basic tools include wrenches, screwdrivers, and pliers, while specialized tools like hydraulic pressure testers and multimeters may be needed for specific tasks. Ensure all tools are in good condition to avoid damaging components. Safety equipment, such as gloves and safety glasses, should always be worn. Refer to the parts manual for a detailed list of required tools and equipment, ensuring compliance with manufacturer recommendations. Using the correct tools helps prevent damage and ensures safe, efficient maintenance operations. Regularly inspect tools for wear and replace them as needed to maintain precision and safety standards.

7.3 Safety Precautions

Always wear protective gear, including gloves and safety glasses, when performing maintenance or repairs. Ensure the scissor lift is on a level surface and properly supported before starting work. Disconnect the battery and hydraulic power sources to prevent accidental operation. Use only Skyjack-authorized tools and equipment to avoid damage or injury. Follow all safety guidelines outlined in the manual and ensure compliance with local regulations. Never attempt repairs without proper training or experience, and consult the manual or contact Skyjack support if unsure. Safety protocols are critical to preventing accidents and ensuring effective maintenance.

Troubleshooting Common Issues

Identify and address common problems like hydraulic malfunctions, electrical faults, or scissor lift errors by referring to the manual or contacting Skyjack’s technical support team promptly.

8.1 Hydraulic System Issues

The hydraulic system in the Skyjack SJIII 3219 is critical for operation. Common issues include fluid leaks, valve malfunctions, or pump failures. Symptoms may include slow lift operation, uneven movement, or excessive noise. Always refer to the parts manual for troubleshooting steps, such as checking fluid levels or inspecting hoses for damage. If problems persist, contact Skyjack’s technical support for professional assistance to ensure safe and effective repairs.

8.2 Electrical System Problems

Electrical issues in the Skyjack SJIII 3219 may stem from faulty sensors, wiring malfunctions, or control panel errors. Symptoms include erratic machine behavior, unexpected shutdowns, or non-responsive controls. Refer to the parts manual for troubleshooting steps, such as checking connections or consulting exploded diagrams for component identification. If issues persist, contact Skyjack’s technical support for specialized assistance. Always use authorized replacement parts to ensure compatibility and safety, as outlined in the manual. Regular inspections can prevent electrical system failures and ensure optimal performance.

8.3 Scissor Lift Malfunctions

Scissor lift malfunctions may occur due to worn or damaged components, improper lubrication, or misaligned parts. Symptoms include uneven lifting, sudden stops, or failure to elevate. Inspect the scissor stack assembly, pivot pins, and hydraulic systems for wear. Refer to the parts manual for exploded diagrams to identify and replace faulty components. Ensure all parts are properly lubricated and aligned. If issues persist, consult the troubleshooting section or contact Skyjack’s technical support for professional assistance. Always use authorized replacement parts to maintain safety and performance standards. Regular maintenance can prevent such malfunctions.

Ordering Replacement Parts

Contact the Skyjack Parts Department via phone, fax, or email to order replacement parts. Use the online parts portal for convenient ordering and verification of compatibility.

9.1 Contacting the Skyjack Parts Department

To contact Skyjack’s Parts Department, call their toll-free number at 1-800-965-4626 or fax at 1-888-782-4825. For international inquiries, reach them at +44 (0)1691 654141. Emails can be sent to parts@skyjack.com. Ensure to provide your equipment’s serial number and specific part details for efficient service. Representatives are available during business hours to assist with orders, part compatibility, and any questions regarding the SJIII 3219.

9.2 Using the Skyjack Online Parts Portal

The Skyjack Online Parts Portal offers a convenient way to search, view, and order parts for the SJIII 3219. Users can access the portal 24/7, browse detailed exploded diagrams, and cross-reference parts with the manual. To use the portal, create an account on the Skyjack website. Once logged in, enter the equipment model or part number to find compatible components. The portal also provides real-time inventory checks and allows users to track orders. Visit www.skyjack.com to access the portal and streamline your parts ordering process.

9.3 Verifying Part Compatibility

Verifying part compatibility is crucial to ensure proper functionality and safety. Use the Skyjack Online Parts Portal or the parts manual to cross-reference part numbers with your SJIII 3219 model. Check the exploded diagrams for visual confirmation of compatibility. If unsure, contact the Skyjack Parts Department for assistance. Always use authorized parts to maintain warranty coverage and adhere to safety standards. Proper verification prevents installation errors and ensures optimal performance of your equipment. This step is essential before ordering or installing any replacement parts.

Warranty and Support

Skyjack offers a 24-month warranty on parts and workmanship for the SJIII 3219. Contact their customer support for assistance with warranty claims or technical inquiries.

10.1 Warranty Coverage for Parts

The Skyjack SJIII 3219 is backed by a 24-month warranty covering defective parts and workmanship. This warranty ensures faulty components are repaired or replaced free of charge. Coverage begins from the delivery date and applies to parts purchased from authorized Skyjack dealers. For warranty claims, contact Skyjack’s customer support team with proof of purchase and detailed issue descriptions. Using authorized replacement parts is crucial to maintain warranty validity and ensure compliance with safety standards. This warranty underscores Skyjack’s commitment to quality and customer satisfaction.

10.2 Skyjack Customer Support Services

Skyjack offers comprehensive customer support services, including a dedicated team available to assist with parts inquiries, troubleshooting, and technical guidance. Customers can contact support via phone, email, or through the online portal. The 24/7 availability ensures prompt resolution of issues, minimizing downtime. Skyjack’s support team is trained to provide accurate and efficient solutions, ensuring optimal performance of the SJIII 3219. Additional resources, such as technical animations and service manuals, are accessible online, further enhancing the support experience. This commitment to customer care reflects Skyjack’s dedication to user satisfaction and equipment reliability.

10.3 Availability of Technical Support

Skyjack provides 24/7 technical support to ensure timely assistance for the SJIII 3219. Customers can access support via phone, email, or the Skyjack online portal. The technical team is equipped to address complex issues, offering troubleshooting and repair guidance. With a global network of certified professionals, Skyjack ensures minimal downtime and rapid resolution. Additional resources, such as technical animations and service manuals, are available online, further enhancing the support experience. This comprehensive approach underscores Skyjack’s commitment to maintaining equipment performance and user satisfaction worldwide.

Environmental and Safety Considerations

Proper disposal of used parts and adherence to environmental regulations are crucial. Always follow safety guidelines to minimize risks and ensure compliance with local standards and requirements.

11.1 Disposal of Used Parts

Proper disposal of used parts from the Skyjack SJIII 3219 is essential to minimize environmental impact. Always adhere to local regulations and guidelines for hazardous waste disposal. Ensure that all fluids, such as hydraulic oils and batteries, are handled and disposed of safely. Use authorized recycling centers or certified disposal facilities to manage scrap metal and other materials. Follow Skyjack’s recommendations for eco-friendly practices to reduce environmental footprint and maintain compliance with safety standards.

11.2 Safety Guidelines for Handling Parts

Always wear protective equipment, such as gloves and safety glasses, when handling parts to prevent injuries. Ensure proper lifting techniques to avoid strain or damage to components. Use appropriate tools for part removal and installation to prevent damage or personal harm. Be cautious of sharp edges or heavy components that may pose a hazard. Follow Skyjack’s safety recommendations and guidelines outlined in the manual to ensure safe handling and compliance with environmental standards.

11.3 Compliance with Local Regulations

Ensure all parts handling and disposal practices comply with local environmental and safety regulations. Properly dispose of hazardous materials, such as batteries or fluids, to prevent ecological harm. Adhere to regional safety standards for equipment operation and maintenance. Obtain necessary permits and certifications for compliance. Consult local authorities or environmental agencies to verify regulatory requirements. Compliance ensures legal adherence and supports sustainable practices for the Skyjack SJIII 3219 scissor lift maintenance and operation.

Additional Resources

Access field options, quick start guides, and pre-delivery inspection forms for comprehensive support. Visit Skyjack’s centralized portal for manuals, technical animations, and environmental data sheets.

12.1 Field Options and Accessories

Explore various field options and accessories for the Skyjack SJIII 3219, designed to enhance functionality and customization. These include additional features like specialized attachments, upgraded components, and optional equipment available through Skyjack’s support portal. Access detailed descriptions and part numbers for easy ordering, ensuring compatibility and optimal performance. Visit Skyjack’s official website or consult the parts manual for a comprehensive list of available accessories tailored to meet specific operational needs and improve efficiency on the job site.

12;2 Quick Start Guides

Quick Start Guides provide concise instructions for rapid familiarization with the Skyjack SJIII 3219. These guides cover essential operations, safety checks, and basic maintenance, ensuring operators can quickly understand and utilize the equipment. Available through Skyjack’s support portal, they complement the parts manual by offering step-by-step directions for immediate use. Designed for efficiency, these guides help reduce downtime and ensure smooth operation, making them invaluable for new users or those needing a refresher on key functionalities.

12.3 Pre-Delivery Inspection Forms

Pre-Delivery Inspection Forms ensure the Skyjack SJIII 3219 is thoroughly checked before use. These forms outline critical components to verify, such as hydraulic systems, electrical connections, and scissor mechanisms. They help confirm that all parts are in working condition, aligning with safety and operational standards. Available in the manual and online, these forms guide users through a systematic inspection process, ensuring reliability and compliance with manufacturer guidelines. Regular use of these forms helps prevent issues and extends equipment lifespan.